Adding a deck to your home is an excellent way to use your outdoor space and add value. However, a new deck must be built correctly and carefully to withstand the elements and serve your family for years. During the interview, ask the contractors about their lead times and whether they guarantee their work. Unforeseen circumstances can cause delays, so having something in writing can help you hold them accountable.

Pro Deck Builders Charleston have websites with customer testimonials, photos of completed projects, and other important information. Taking a few moments to check these can help you whittle down your list of contractors. Also, ask around to find out if any of your friends or neighbors have had their decks built recently and how they worked with the contractors. People are usually eager to share their contractor experiences, good and bad, so this is a great way to get a broader range of opinions about different companies.

If you have narrowed down your choices, conducting brief phone interviews with each is a good idea. You can learn more about each builder’s availability, work style, and product offerings during this stage. You may also be able to gauge whether their design style aligns with your own.

Ask prospective contractors about the steps to prepare and build a new deck. For example, some builders use a special process to minimize the fire risk in their projects by using wood certified as fire-rated. It is particularly important for homes located in areas susceptible to wildfires.

It is also good to see examples of the builder’s previous work before hiring them. It will give you a better sense of their work quality and attention to detail. Look for well-finished edges, sturdy construction, and attractive color schemes.

Meeting your potential contractors in person for an onsite project inspection is also a good idea. It will allow you to discuss further any issues that surfaced during your initial phone conversations and confirm that their lead times and completion dates are realistic.

As you interview potential contractors, ask about their experience and whether they offer an artistry guarantee. If they say yes, ask for specifics, such as what kind of decks are covered and for how long. It is an important question to ask, as it can save you a lot of hassle in the future. For instance, if the contractor offers a warranty on their work but only covers certain materials, this could be problematic.

It is also good to ask how they plan to handle the permit process. Most regions require that homeowners obtain a permit before building a deck. It ensures your deck is up to code and meets local safety standards. Finding a contractor that can get the tickets for you can help streamline the process and ensure that everything is done correctly.

Lastly, be sure to ask about their crew composition. Some deck builders use subcontractors to complete their jobs, while others employ their crews. It is generally easier to work with a company with its employees as you will be more familiar with their skill levels and personalities.

Once you have narrowed your choices, make a shortlist and arrange to meet with them in person. It will allow you to see their work firsthand and determine if their vision aligns with yours. It will also give you a better sense of their work ethic and communication style. Meeting face-to-face will also allow you to ask questions and help you decide which deck builder is right for you.

A top-tier deck builder should be insured and licensed to operate in your area. It shouldn’t take more than two seconds to ask a contractor whether they’re insured and to show you proof of their insurance and licensing. If they stall or refuse, that’s a red flag.

They should also have liability insurance to cover any damages that occur during the construction process. A comprehensive workers’ compensation insurance policy is also important for a contractor’s employees to have, as it will cover any medical expenses or lost wages in the event of an injury at work.

It would be best if you also asked a potential builder what material they’d prefer to use for your deck, as this can significantly impact the cost. Different materials have benefits and drawbacks, and you’ll want to find one that fits your style, home, and budget.

Lastly, you should ensure your contractor is current on local regulations and requirements for building a deck. Your project may require council approval or a permit, depending on where you live. A good deck builder should be able to advise you on the best options and help you sort out all the necessary paperwork.

Additionally, your builder should have a commercial auto insurance policy for their work vehicles, as these are typically excluded from personal policies. It will ensure they’re covered while going to and from job sites and parked on the street. It is a vital protection for any business owner and should be required for all contractors. This type of policy is often called Business owners insurance or BOP coverage and will include general liability, property, workers’ compensation, and more.

Everyone will tell you that when it comes to home construction, always hire a licensed contractor. It’s one of the most basic bits of advice that gets shared more often than anything else. Unfortunately, many homeowners still ignore this recommendation. If you’re looking for a residential deck builder, this is one of the most important aspects you should check for.

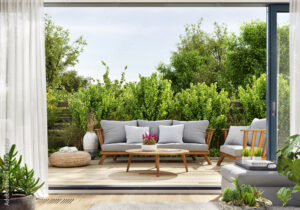

A deck is a platform built outdoors, elevated from the ground, and usually connected to a building. It can be used for seating, cooking, and other purposes. It is generally enclosed with a railing for safety, and access can be gained through doors and from the ground via stairways.

Most people enlist local contractors to build their decks or attempt to do the project themselves to save money and time. However, this dangerous approach can result in shoddy artistry and out-of-code projects. Decks not constructed properly can collapse, which can be fatal to anyone on them.

Another problem with going the DIY route is that you can void the manufacturer’s warranty on deck materials if installed incorrectly. Lastly, failing to obtain a permit for a deck or porch can sabotage any future attempts to sell your property.

In short, if the residential deck builder you’re considering has no license, run away as fast as possible. A licensed contractor is familiar with and follows the building codes that are in place for your safety and the structural integrity of your deck. Furthermore, they will have the experience and knowledge to build your deck correctly.

When evaluating your options for residential deck builders, ask for references from previous clients. It will help you get a better idea of the quality of work they provide and their level of customer service. A reputable contractor will be happy to share this information with you, and they will also be willing to answer any questions that you may have.

When choosing a professional residential deck builder, finding one with a strong track record of success and excellent communication with their clients is important. The best way to do this is by asking friends and family for recommendations or visiting local home improvement stores to see what kinds of outdoor living projects they have completed. In addition, it is important to find out whether or not the deck builder has a valid contractor’s license in your state or municipality and if they have liability insurance in case something goes wrong during construction.

Once you have found a residential deck builder that meets your criteria, discuss the project details with them. It will allow you to ensure they understand what you are looking for and that the design will meet your needs. Also, this is the time to bring up any concerns that you may have about the procedure or the overall look and feel of the deck.

It is also a good idea to ask about the different materials that can be used in deck construction and their pros and cons. For example, wood offers a natural aesthetic but can be expensive and requires more maintenance than other materials. It is also helpful to know if the contractor will be handling the permit process or if they will be subcontracting this aspect of the job out to another company.